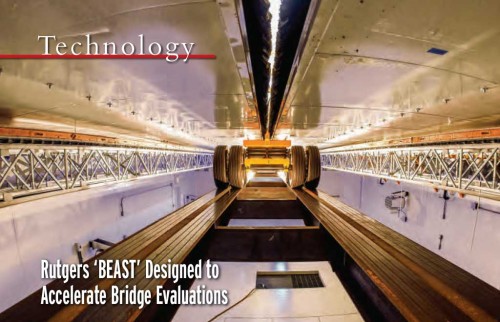

This month’s edition of Civil Engineering Magazine highlights the world’s first accelerated testing facility for full-scale bridges: the Bridge Evaluation and Accelerated Structural Testing Lab (BEAST).

This month’s edition of Civil Engineering Magazine highlights the world’s first accelerated testing facility for full-scale bridges: the Bridge Evaluation and Accelerated Structural Testing Lab (BEAST).

The BEAST was designed by a team of Rutgers engineers and other bridge experts, with assistance from Applied Research Associates, Inc. (ARA). ARA constructed some of the massive components of the BEAST, especially a set of parallel steel I beams 120 ft long by 7 ft deep, at its plant in Randolph, VT. DuBois & King supported ARA with civil/site design, permitting, and structural engineering services including design of concrete abutments and foundation design for the environmental simulation enclosure. Site engineering included utility relocations, coordination of electrical design for 1200 KVA and as-built survey of the rail system. Click on the article link below to read more about the design and the future of testing for America’s bridges.

Read the article in: Civil Engineering Magazine (Feb. 2016)